Features

- Fully automated test programs and data analysis

- Conditioning mode provides unparalleled repeatability

- Range of sample size, 10ml to 160ml (in addition a 1ml Shear Cell is available)

How it works

The FT4 employs unique technology for measuring the resistance of the powder to flow, whilst the powder is in motion. A precision ‘blade’ is rotated and moved downwards through the powder to establish a precise flow pattern. This causes many thousands of particles to interact, or flow relative to one another, and the resistance experienced by the blade represents the difficulty of this relative particle movement, or the bulk flow properties.

Excellent reproducibility and sensitivity, this is achieved by moving the blade in a precise and reliable way. The advanced control systems of the FT4 accurately set the rotational and vertical speeds of the blade, which defines the Helix Angle and Tip Speed.

Powder Flow Testing with the FT4 Powder Rheometer

FT4 Powder Rheometer Methodologies

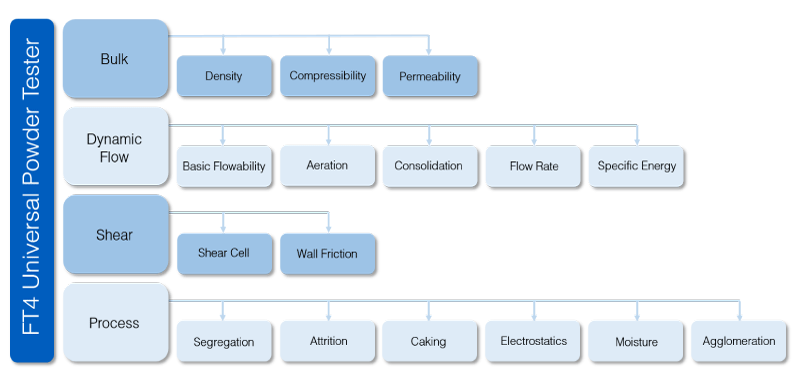

The FT4 is a truly universal powder flow tester, with four categories of methodologies, defined as Bulk, Dynamic Flow, Shear (in accordance with ASTM D7981) and Process.

Proven Applications

The FT4 has application in all powder processing industries, including Pharmaceuticals, Fine Chemicals, Food, Cosmetics, Toners, Metals, Ceramics, Plastics, Powder Coatings, Cements and Additive Manufacturing. Applications extend to:

- Die / Capsule Filling

- Tablet Compression

- Hopper Flow

- Wet Granulation End Point & Scale Up

- Flow Additive Selection & Optimisation

- Humidity Effects

- Electrostatic Charge

- Mixing / Blending

- Feeding

- Segregation

- Attrition

- Dry Powder Inhalers

- Caking

- Milling

- Conveying

- Wall Friction & Adhesion

- Hopper Design

- Compact Hardness & Payoff

- Vacuum Filling

- Agglomeration

Whether your objective is to optimise a formulation in a development environment, predict in-process performance, understand batch differences, or to ensure the quality of raw materials or intermediates, the FT4 will provide valuable and unique information that will help you address your powder flow challenges.

Please click on the images below for more in-depth information