The Importance of Conditioning

Anyone who has worked with powders will know how easily they change their density, just as a result of handling them. Tip them from a beaker and they aerate, or tap the beaker on the bench and observe a reduction in volume as the powder becomes compacted.

These changes in density are a consequence of changes in the stress applied to the powder. As discussed previously, variation in stress level is likely to have a major impact on how the powder behaves, within a process or application, but also during a measurement. It is therefore essential to ensure the powder is prepared for any test by first establishing a uniform stress in the powder bed and eliminating pockets of air or localised compaction.

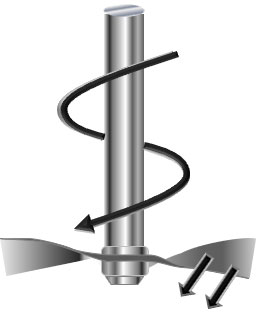

This preparation step is called Conditioning and is a simple, but effective mechanical process designed to prepare the sample for the following measurement. Utilising the same unique technology that is used in the dynamic methodologies (see previous pages), the Conditioning process involves gentle displacement of the whole sample in order to loosen and slightly aerate the powder. The aim is to disturb and gently drop each particle in order to construct a homogenously packed powder bed, removing any precompaction or excess air and ensuring the results from the following test are independent of how the operator handles the powder and places it into the testing vessel.

Powder Conditioning with Blade

A conditioning cycle is usually completed prior to every test in order to remove the variability introduced by the operator during loading of the sample, and any residual compaction from previous tests. The exception is where an intentionally consolidated sample is being evaluated, in which case conditioning is not employed.

Return to FT4 Page